Are you looking for a packing machine but worry about the space and too complicated?

Do you trying to find a economical packing machine model but with high quality and assured service?Here the 2 in 1 weighing and packing machine can be your first choice!

It was a new type packing machine which assemble VFFS machine and weigher together to save space. Machine It is suitable for weighing and packaging of granule slice shape, such as cereal, pasta, candy, seed, chips, coffee beans, nuts, puffed food, biscuit, chocolate, pet food, frozen foods, etc. it is also auitable for non-food industry, such as screws, bolts and other small hardwares.

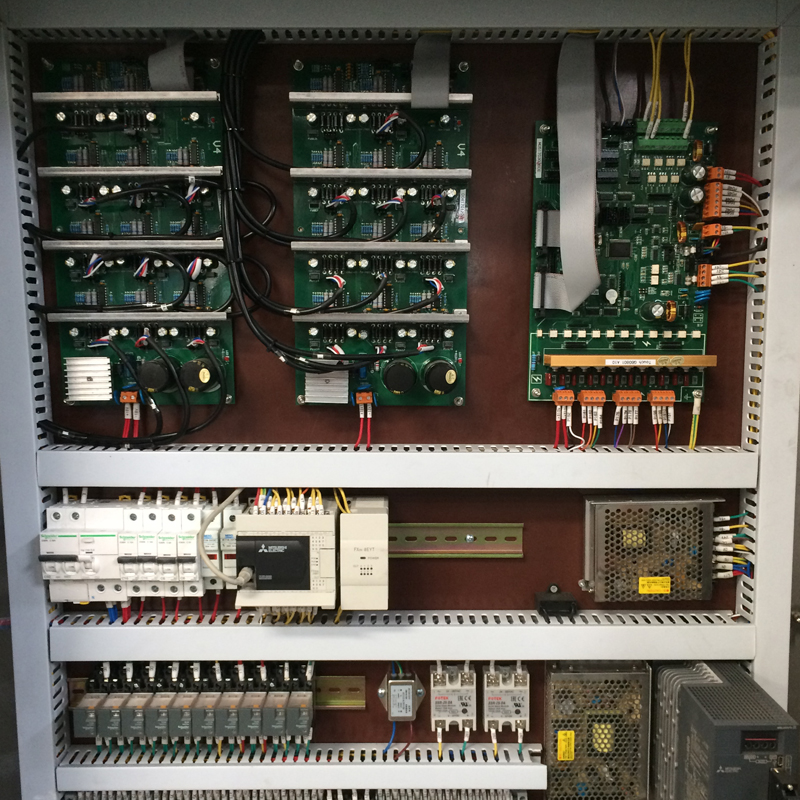

Machine adopt PLC control system and air cylinder for operation, make sure each parts can be working independent. Easy for maintain and cleaning. Nitrogen gas inflation, batch number printing, handing hole making, etc function was available. Bag type like: pillow bag, 4 sides bag seeal, gusset bag, quad bag was no problem for this model.

1.Machine Introduction:

A. Hopper: using to delivery production into packing machine bag former.

B. Multi-head weigher: using to automatic weighting and filling the product, very accurate, the weigher's computer determines the weight of product in each individual weigh hopper and identifies which combination contains the weight closest to the target weight.Then opens all the hoppers of this combination and the product falls, via a discharge chute, into a bagmaker or, alternatively, into a distribution system which places product.

C. Sealing part: adopt servo motor film pulling, servo motor sealing, working with horizontal zig cut effect, make the packing speed faster and bag sealing better.

2.Machine Features:

a). Compact design, suitable for limited height within 3000mm.

b). Save you cost and installation space.

c). Combination design, but separately HMI for weigher and VFFS for easy after-sale service maintainence.

d). Widely used on different kinds products, tailor-made on your project requirements.

3.Packing film options:

Cellophane/polythene ,polyester/Coating aluminum/polythene, polyester /polypropylene, bopp film nylon compounded film etc, which over 2 layers and can be heat-sealed.

4. Technical parameter:

Sachet type | Pilow bag, 4 sides bag seal | |

Sachet size range | Max.Size | 100mm(W)×350mm(L) |

Min.Size | 100mm(W)×400mm(L) | |

Filling weight range | ≤5kg | |

Packing speed | 10-50 bags/min | |

Electricity Power | 3.5KW | |

Power Electricity | 220V /380V, 50 / 60Hz | |

Film Roll Diameter | ≤Φ450mm | |

Max Film Width | 720mm | |

5. Machine drawing:

6. Machine outside look:

7. Machine detail display:

8. Packaging machine bag sealing type and effect:

9. Machine video on Youtube:

10. Machine real project cases:

http://www.packhomegroup.com/en/project-case_l146_1.html

11. Our company strength:

A. 24 hours standby for machine inquiry and technicial support need.

B. Provide on site installation and debugging service.

C. All machine with CE certification.

D. With distributor in: Italy, Japan, Korea, USA, Australia, Malaysia,Africa, South America market etc.

12. Frequently Asked Question

A. Price item options: EXWORK,FOB,CIF,CFR

B. Payment terms : T/T 30% deposit, 70% balance before shipment.

C. Delivery Time : 20- 30 days depending on packing requirement.

D. Shippment : By sea or by air.

E. Warranty time :One year free for replacement of wearing parts, cost price beyond warranty

13. OEM and ODM Service

For better offer suggestion and prepare quotation, hope we can know below info from you:

A. Your bag size

B. Your bag picture

C. Packing weight

D. Packing speed requirement

E. Exactly product need to packed